Botanical Name:

(Theobroma cocoa)

Aroma:

Unrefined Coca Butter has a chocolatey aroma.

Refined or Deodorized is free of aroma.

Texture:

Solid hard butter, melting point is 94 F

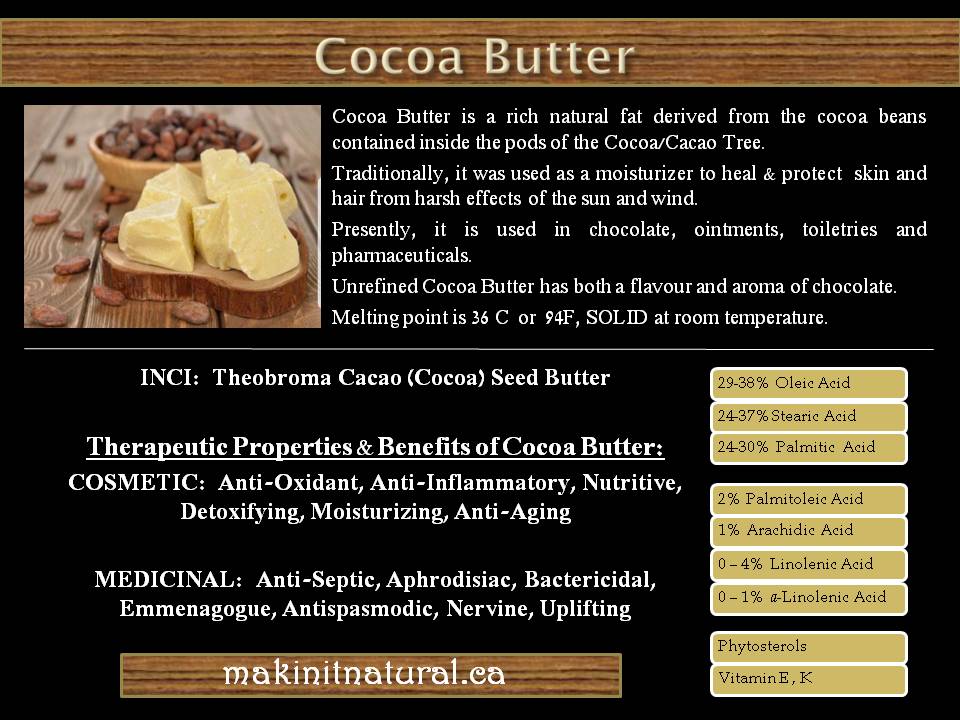

Components:

Lipid

Colour:

Unrefined is a tan colour.

Refined or deodorized is white.

Shelf Life:

Up to 5 years

Store in a Seals Container in dark place

Usage Rates:

Balms: 5-100%

Hair Conditioners: 1-5%

Lotions & Creams: 5-20%

Soap: 5-20%

Cacao pods are harvested manually. Pulling the Cacao pods off the trees can potentially result in damage to the flower cushion or the bark, thus the pods are typically cut from the trees with the aid of machetes or knives.

Inside a ripe Cacao pod, there are between 20 and 40 beans that are encased in a sweet, edible, slippery pulp. They are all joined together by a placenta. The beans are manually scooped out either immediately or after a few days. Next, heaps of the wet beans are placed in baskets, in specially designed wooden fermentation boxes, or on a flat and dry surface, where they are allowed to ferment for up to 10 days. Fermentation naturally breaks down the pulp, eliminates the bean/seed coat and the germ, and develops the bean flavor. The beans are turned or stirred to allow for better air circulation throughout the mass for optimal fermentation. Next, the moisture content of fermented beans is reduced by drying them, either artificially or in sunlight. Dried beans are sorted manually or mechanically to remove debris as well as beans that are flat, germinated, moldy, or broken.

There are 2 stages at which Cocoa Butter can begin to be processed from the seeds/beans: Before Germination and After Germination. Cacao seeds that are processed before they have begun to germinate will produce ordinary Cocoa Butter, ranging in color from off-white or light beige to pale-yellow. It may retain the tempting scent of chocolate. On the other hand, Cacao beans that are processed after they are allowed to germinate will produce Black Cocoa Butter, which has the brown color of chocolate and the aroma of roasted cacao.